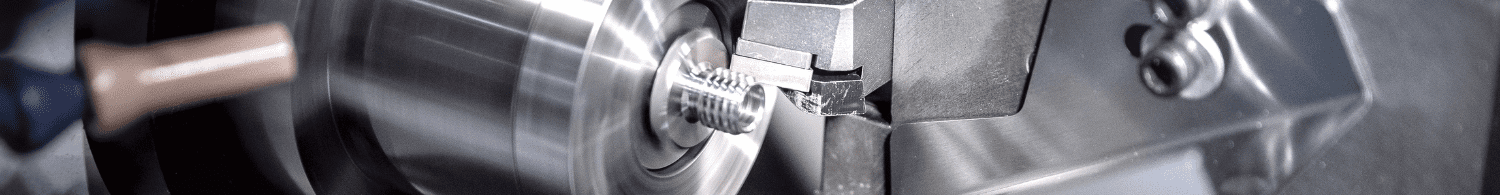

Machining Services

Since 2008, AOP Technologies has been providing innovative solutions in plastics machining. Now with the addition of our new wire stripper division, AOP has made a significant investment in tooling and labor resources for the machining of metals.

Our tooling options include:

- 2 – 3 axis CNC mills

- 2 – CNC vertical Trak mills

- Wire EDM

- Sinker EDM

- CNC Lathe

- Laser Engraver

- 2 – Surface grinders

- Tool grinder

- Cold saw with Tiger stop

- Horizontal band saw

- Sandblast cabinet

- And much more…

How We Approach Machining

Plastics Machining Services

With so many machining and fabrication shops out there, it would seem like finding a quality plastic parts supplier would be a relatively simple endeavor, but it is not so. The reality is that your run-of-the-mill machine shops deal primarily in metal materials – not plastic.

Machining plastics requires nuanced expertise. Many of the properties of plastics like increased thermal expansion, low melting points, and elasticity make it a difficult proposition for maintaining an exact tolerance. Plastics machining & fabrication requires the expertise and experience many don’t have.

For more than a decade now, AOP’s machine shop has mastered the techniques required to achieve precision results in a repeatable manner when machining different industrial plastic materials. With a dedicated staff including engineering support and quality control, you can be assured we have the expertise to get your plastic machining & fabrication job done right that results in high-performance plastics. Whether you require ABS, Acetal (Delrin), UHMW, Nylon, PVC, Polypropylene, Polycarbonate, or other plastics, let AOP use our expertise to provide a fabrication solution that fits your needs.

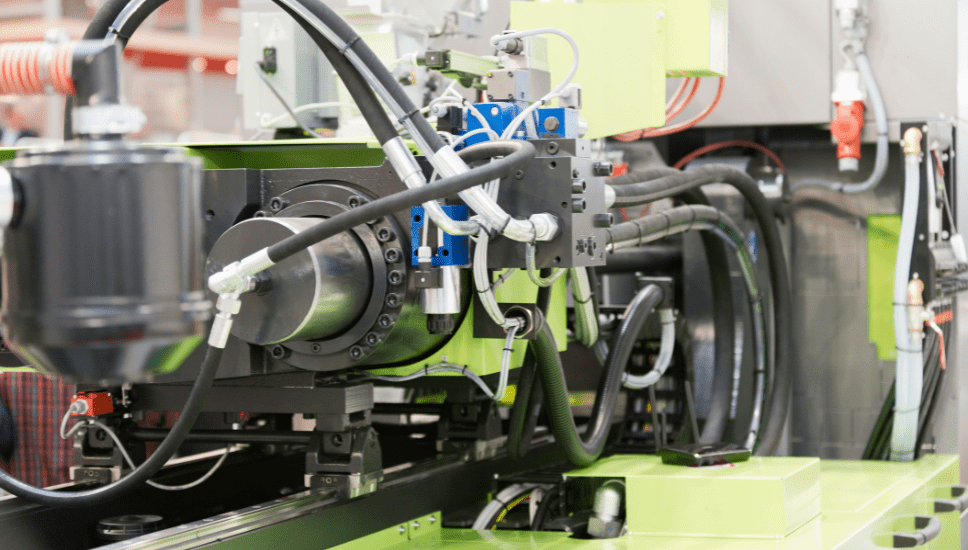

Metal Machining Services

With the acquisition of Western Industrial Products, AOP now boasts a complete machine shop for metal part fabrication. We have further invested in a staff of highly qualified machinists who boast more than 100 years of combined experience. At AOP our capabilities make us well suited for a variety of machining projects such as:

- General machining of ferrous and non-ferrous metals

- Prototyping or pre-production items

- Small production runs

- Custom fixtures and tooling

- Surface grinding

All of this along with engineering support and production capabilities make AOP Technologies a wise choice for the customer looking for great value in a comprehensive package. As an ISO 9001/2015 registered company, AOP is proud to work with clients in Oregon & Washington State including Seattle & Tacoma in medical device manufacturing, oil and gas refining, food and beverage, and many others who have trusted us with their critical thermoplastic component CNC machining.

Why Choose AOP Technologies?

AOP has earned an excellent reputation servicing the fluid power industry with premium product offerings for over 55 years. AOP was founded in 1963 in Portland, Oregon under the name Air-Oil Products Corporation. In the early days, our business was a distribution of sealing products servicing fluid power customers in Washington, Oregon, and Idaho. We soon became the Pacific Northwest’s largest distributor of Parker Hannifin seal products.

Within the next few years, our company expanded and diversified to include the distribution of pneumatic and automation components. Then in 1999, we expanded our business yet again, this time to include contract manufacturing services. We have since become an industry leader with our focus on quality work, competitive pricing, and on-time delivery.

Today we have a 20,000 square foot facility in Auburn, Washington with over 5,000 square feet dedicated to industrial contract manufacturing and plastics machining services including medical device contract manufacturing. Our contract manufacturing division is staffed by highly trained assembly professionals and machinists who are supported by our experienced engineering staff, production management, and quality control specialists.

Our entire staff participates in a rigorous training program built upon a comprehensive library of processes developed through our ISO9001:2015 certified quality program. All departments within our organization are audited annually both internally by our quality control department, and externally by an accredited 3rd party auditor. This is done to ensure both quality and consistency in manufacturing for the customers we serve.

Our business is generally viewed as a high-mix low volume contract manufacturer. We boast an extensive assortment of specialty tooling and automated equipment giving our technicians the ability to very quickly convert assembly lines and ramp up production.

We honor the trust our customers put in us and view those relationships as partnerships. We realize that what makes us successful as an organization is our customer’s success. To that end, we continually invest in tooling, technology, and training in order to provide our customers with premium quality and exceptional value. Our aim is to strive to be the premium solution for manufacturing services for the customers we serve.

If you have a project opportunity and are considering the outsourcing of manufacturing services, we ask that you contact one of our representatives. Let us show you how partnering with AOP Technologies can add value to your business and give you a competitive edge in the marketplace.