Manufacturing Automation

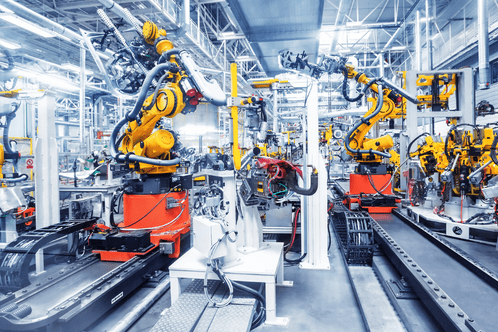

AOP Technologies provides industrial automation solutions for OEM manufacturers and is a leading distributor of pneumatics, air moving products, controls and automation, liquid handling solutions, and seals and O-rings.

We serve the Manufacturing Automation markets throughout the Pacific Northwest with key brands that include Air-Logic, Air-Vac, Automatic Valve, American Cylinder Co., Clippard, Colder (CPC), Compact Automation, DVP, Freelin-Wade, Gast, Kawasaki, Mem-co, Metal Work, Omron, Parker, Pisco, Schmalz, and T-Slots.

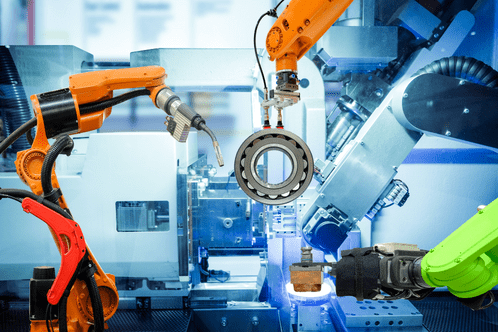

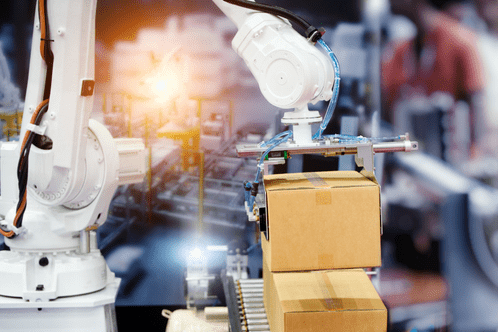

AOP Technologies can assist with the selection of industrial automation products such as pneumatics, electronic motion and control, material handling and robotics.

Our resources run deep! We work closely with our vendors engineering and product managers to make sure we’re selecting the best products for your application. Where standard components may not fit the application, we often have resources for modified standards or completely custom products to fit your unique applications.

CUSTOMER BENEFITS:

ORDER ONE FINISHED ASSEMBLY.

- Instead of ordering, receiving, and stocking several parts, you can order completed assemblies under one part number.

ONLY ORDER WHAT YOU NEED, WHEN YOU NEED IT.

- AOP can stock your assemblies ready to ship the same day you order

YOUR ASSEMBLIES ARE BUILT, TESTED, INSPECTED, CERTIFIED, LABELED, AND PACKAGED.

- Ready to go into your products or directly to your customers.

AOP CONTRACT MANUFACTURING PROCESS:

- AOP thoroughly reviews your documents, requirements and expectations.

- AOP creates the manufacturing processes and documents needed to ensure your products are built accurately and consistently.

- AOP creates detailed part specifications for purchasing and inspecting your custom parts.

- AOP procures and warehouses your parts.

- AOP inspects customer’s fabricated parts. Custom fabricated parts are inspected to aerospace standards

- AOP’s experienced staff builds your assemblies.

- AOP tests all assembled products per customer requirements

- AOP label’s assemblies and products to meet your requirements (including bar coding)

- AOP inspects assemblies for compliance to your specification

- AOP issues certificates of compliance.

- AOP provides traceability. All products built are lot numbered and traceable.

- AOP packs and ships your products. Products are packed and shipped per customer specification. Custom packages available as required.

PARTNERSHIPS:

- We believe in truly partnering with our customers!

- Partnering requires both supplier and customer derive value from the relationship.

- We strive to achieve this because we know it’s key to our growth and longevity.

- We believe value is best created by combining the products and services our customers need.

- If we can help you be successful…we will be successful!