Kawasaki Industrial Robot Partner

Based on 50 years of experience in robotics, Kawasaki Robotics is a leading supplier of industrial robots, robotic arm and robotic automation systems with a broad product portfolio, able to service a wide range of applications all around the world.

A Kawasaki Industrial Robot for every application:

- Palletizing

- Machine Tending

- Arc and High-Speed Spot Welding

- Pick and Place

- Electronics

- Food and Beverage

- Logistics

- Aerospace

- Automotive

- Medical and Pharmaceutical

- Cleanroom Applications

- Painting

- Assembly

- Materials Handling

- Semiconductor

- Metal Manufacturing

- Foundry

- Petrochemical Products

- Machinery

- Ships and Rolling Stock

Kawasaki

Product Lineup:

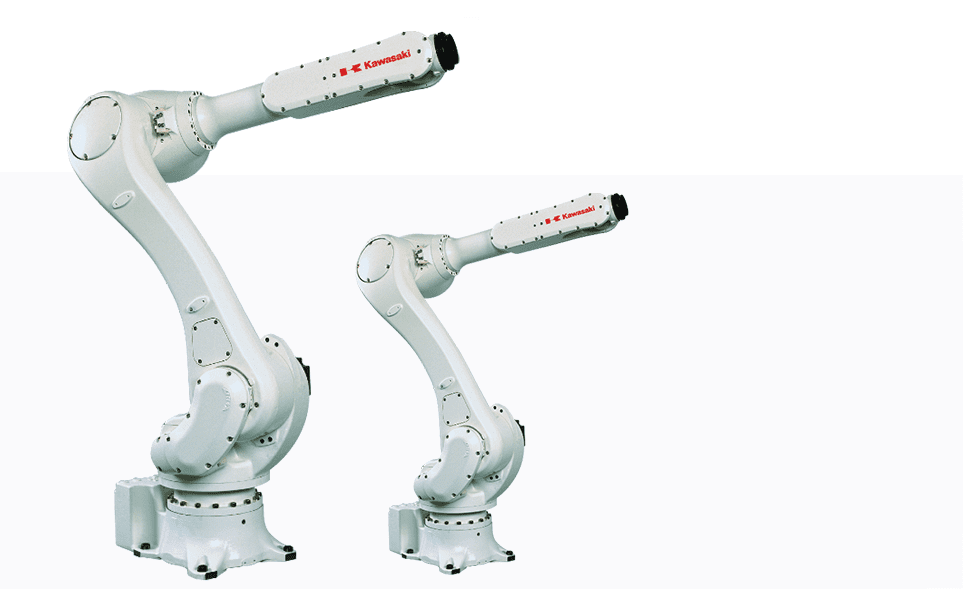

- Robots: Kawasaki provides high-performance robots with payload capacities ranging from 3 to 1,500 kg, suitable for applications such as assembly, material handling, machine tending, palletizing, picking, painting, sealing/dispensing, polishing, deburring, arc and spot welding, and wafer transfer.

- Controllers: Their state-of-the-art robot controllers are designed to meet the demands of any project, ensuring seamless integration and optimal performance.

- Other Products: Kawasaki offers simulation tools, offline programming software, safety systems, vision systems, and more to enhance automation processes.

- K-AddOn Products: A curated list of equipment from partner companies that integrate seamlessly with Kawasaki robots, expanding their functionality and application scope.

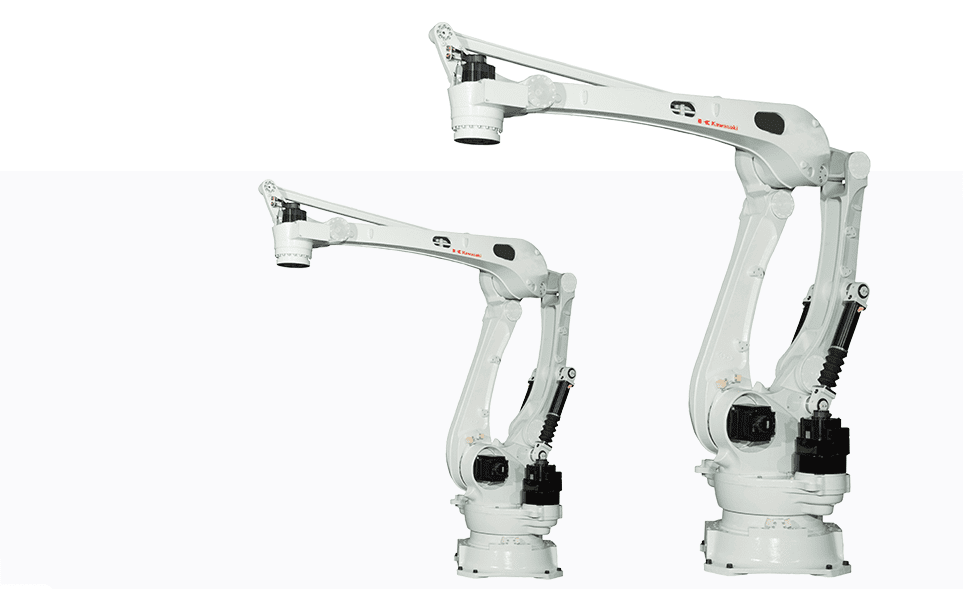

CP SERIES

Kawasaki’s newest line of high-speed palletizing robots and robotic arms, the CP series, provides industry-leading cycle times and offers a wide range of payload options (from 180 kg to 700 kg) with a long reach for increased throughput.

KAWASAKI RA020N ROBOT

Kawasaki arc welding robots use state-of-the-art technology to rival the quality of a skilled human welder. The Kawasaki RA020N robot has a maximum payload capacity of 20 kg which accommodates larger torches.

- Kawasaki’s industrial automation product line has robots to handle payloads from 3 kg to 1,500 kg

- Kawasaki’s palletizing robot line consists of seven unique models with payload capacity from 20 kg to 700 kg and reach capacity from 1725 mm to 3255 mm.

- State-of-the-art clean robots meet the healthcare industry’s processing equipment specifications

- Kawasaki’s robots can safely handle delicate components weighing only grams to bulky castings weighing 1,500 kg

- Human and environmentally friendly robot systems provides a high level of skill and intelligence

Notable Products:

- YF Series high-speed Delta Robots are for pick-and-place applications such as assembly, material handling, food handling and secondary packaging in markets including pharmaceutical, cosmetics, electronics, food processing, packaging or anywhere light-duty, high-speed movements are needed.

- MC Series medical and pharmaceutical 6-axis articulating robots meet healthcare industry requirements for accuracy, consistency and cleanliness, making them ideal for assembly, dispensing, inspection and material handling applications. A stainless steel version is suitable for VHP sterilization.

- NT, TTJ, NTH and NX series, high-speed silicon wafer transfer robots meeting SEMI-F47 and SEMI-S2 standards and can assess 3-4 FOUPS without a track. The TTJ series offers high-speed transfer in high and low pass lines thanks to a unique high-rigidity telescoping mechanism.

- CL series six-axis collaborative robots offer payloads ranging between 3kg to 10kg with reaches of 590 – 1300mm. Collaborative robots are used in many applications, such as machine tending, light-duty palletizing, material handling and more, where operation is in close proximity to human beings.

- BA and RA series arc welding robots embody a “simple and friendly” concept. They can be connected to the welder with a single cable for easy deployment. A wide range of hardware and software options help improve the quality of arch welding operations.

- Cubic-S: A robot safety system that allows users to build advanced and flexible safety systems by monitoring and limiting robot motion, including external axes.

Commitment to Quality:

Kawasaki Robotics is dedicated to delivering products that meet the highest standards of quality. Their extensive experience in prototype development and comprehensive verification data ensures that every robot is designed to perform reliably in demanding environments.

Why Work with AOP Technologies & Kawasaki Robotics

Kawasaki’s broad product portfolio services a wide range of applications across diverse industries. For optimum control of the manipulator, Kawasaki’s high-performance lineup is supported by their continuous development of control technology to improve function and operation.

We know that you will benefit from the technology and experience in your future automation projects to increase production, lower costs, and improve quality. AOP has both mechanical guarding and electronic safety equipment to help you address even the most stringent safety requirements. Contact AOP Technologies to discover how Kawasaki Robotics can improve your productivity and quality.