- Loading and unloading

- Assembling

- Screwing

- Palletizing

- Gluing

- Testing

- Soldering

- Machine Tending

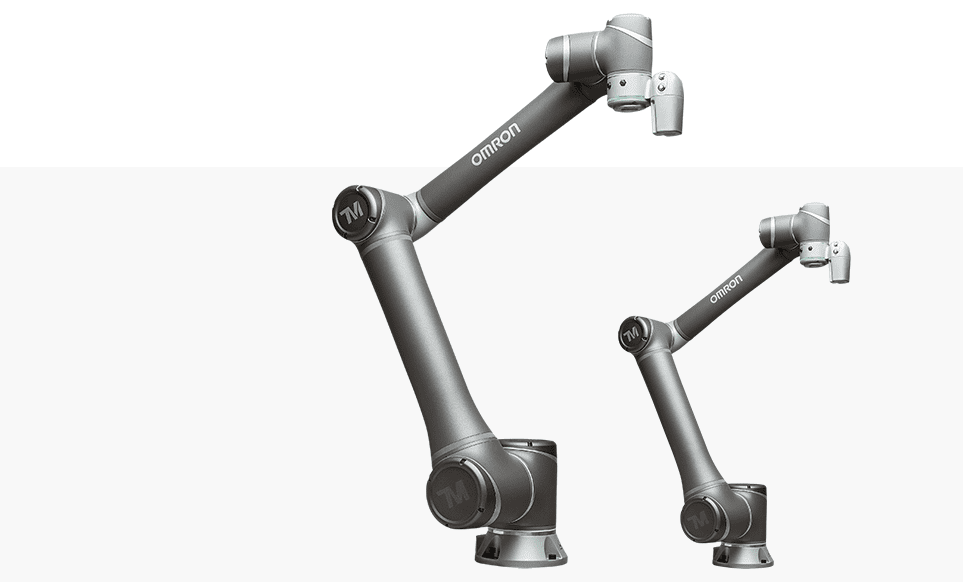

OMRON TM ROBOTICS

Built for the future of automation & designed for modern manufacturing. This robot is Industry 4.0 ready.

- Fast and simple programming

- Built-in intelligent vision

- This product complies with the combined scope of ISO 10218-1:2011, ISO/TS-15066 and optionally, SEMI S2 Certification

- Fast changeover using TMvision and Landmark

- Advanced control

- External Camera Support: Optional software to support 2 additional GigE vision cameras

Why Work With AOP Technologies & Omron TM Robotics

We believe Omron TM series cobots are second to none and offer some key advantages such as integrated vision, remote camera support, heavier payloads and longer reaches than some of the other brands. We also know that a successful installation means selecting the proper end-of-arm tooling. Whether using mechanical or vacuum grippers, or a completely unique and custom gripping system, AOP has the technical capabilities and years of experience with electronic and pneumatic components, to help you develop a solution that will work best for you.

Cobots are designed to work side by side with a human. That said, Omron TM Robotics may be the appropriate robot for an application that does pose a risk to humans and thus requires safety guarding of some type. If that is the case, AOP has both mechanical guarding and electronic safety equipment to help you address even the most stringent requirements.